ORIENTAL MOTOR U.S.A. Corp.

1001 Knox Street

Torrance, CA 90502

1-800-GO-VEXTA (468-3982)

ORIENTAL MOTOR U.S.A. Corp.

1001 Knox Street

Torrance, CA 90502

1-800-GO-VEXTA (468-3982)

The AR Series adopts our AlphaStep technology closed loop control so the motor does not lose synchronism even when subjected to abrupt load fluctuation or acceleration. Requires AR Series Driver.

| Items |

ARM66AC 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $192.00

|

ARM66AC-T3.6 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $311.00

|

ARM66AC-T7.2 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $311.00

|

ARM66AC-T10 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $323.00

|

ARM66AC-T20 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $323.00

|

|||||

| Frame Size | - 2.36 in | |||||||||

| Motor Length | - 2.54 in. | - 4.33 in. | - 4.33 in. | - 4.33 in. | - 4.33 in. | |||||

| Driver Voltage Input Power | - AC | |||||||||

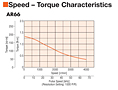

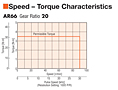

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

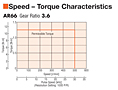

-

Speed - Torque Characteristics |

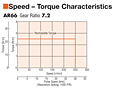

-

Speed - Torque Characteristics |

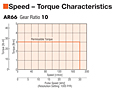

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

| Holding Torque | - 170 oz-in | - 176 oz-in | - 352 oz-in | - 416 oz-in | - 480 oz-in | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - 3.6 :1 | - 7.2 :1 | - 10 :1 | - 20 :1 | |||||

| Backlash | - | - 35 arc min (0.584°) | - 15 arc min (0.25°) | - 15 arc min (0.25°) | - 10 arc min (0.167°) | |||||

| Lost Motion | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Permissible Speed Range (r/min) | - | - 0 ~ 500 | - 0 ~ 250 | - 0 ~ 180 | - 0 ~ 90 | |||||

| Rotor Inertia | - 2.1 oz-in² | |||||||||

| RoHS Compliant | - These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

| Safety Standards | - UL CSA EN CE | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb | |||||

| Permissible Thrust Load | - 1.98 lb | - 9 lb | - 9 lb | - 9 lb | - 9 lb | |||||

| Permissible Thrust Load | - | |||||||||

|

|

||||||||||