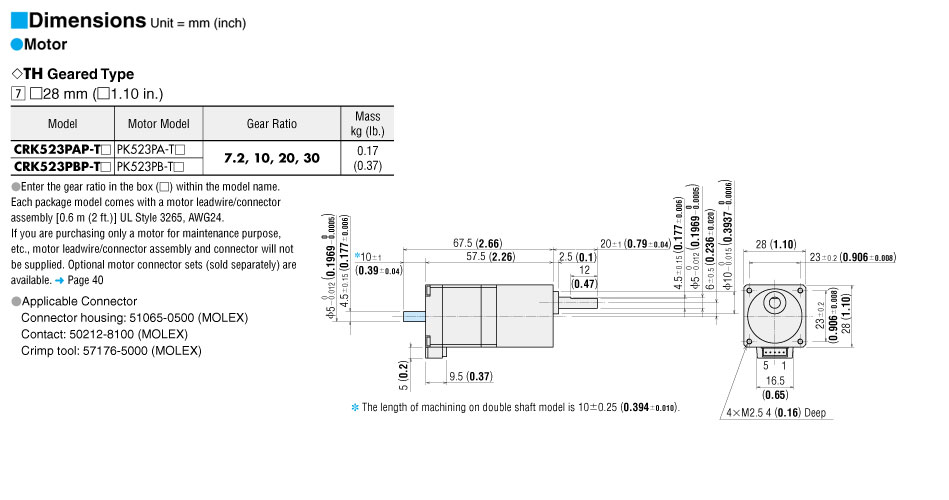

Frame Size

|

-

1.1 in28 mm

|

Motor Length

|

-

2.26 in.57.50 mm

|

Basic Step Angle

|

-

0.72°

|

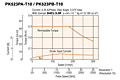

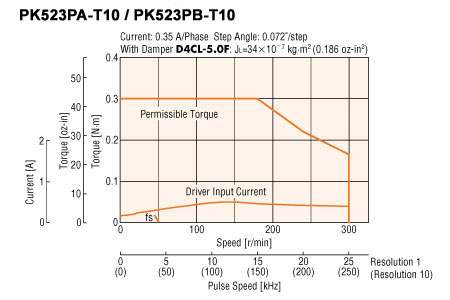

Speed-Torque Characteristics

|

-

Speed-Torque Characteristics

|

Holding Torque

|

-

42 oz-in0.3 N·m

|

Current per Phase

|

-

0.35 A/phase

|

Type

|

-

Geared

|

Shaft/Gear Type

|

-

Taper Hobbed Gear

|

Gear Ratio (X:1)

|

-

10 :1

|

Gear Type

|

-

Taper Hobbed, Low Backlash (up to 45 arc min), Offset Shaft

|

Backlash

|

-

60 arc min (1°)

|

Motor Connection Type

|

-

Connector

|

Shaft

|

-

Double

|

Step Angle

|

-

0.072 °

|

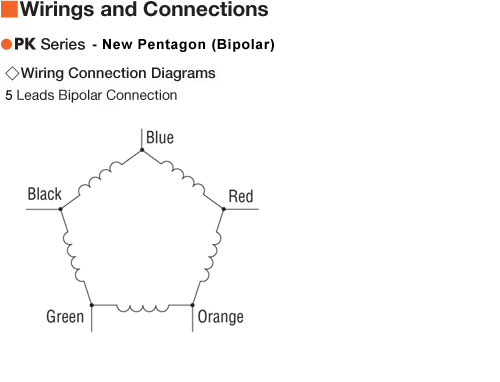

Connection Type

|

-

New Pentagon (Bipolar)

|

Lead Wires

|

-

5

|

Rotor Inertia

|

-

0.049 oz-in²9×10-7 kg·m²

|

RoHS Compliant

|

-

Yes

|

Safety Standards

|

-

UL CSA CE

|

Insulation Resistance

|

-

100 M Ω minimum under normal temperature and humidity, when measured by a 500 VDC megger between the windings and the motor casing.

|

Dielectric Strength

|

-

Sufficient to withstand 0.5 kV, 50 Hz or 60 Hz applied for one minute between the windings and casing, under normal temperature and humidity.

|

Temperature Rise

|

-

Temperature rise of the coil measured by the Change Resistance Method is 176°F (80°C) or less (at rated current, at standstill, five phases energized).

|

Insulation Class

|

-

Class B [266°F (130°C)], Recognized as Class A 221°F (105°C) by UL standard

|

Ambient Temperature Range

|

-

14°F ~ 122°F (-10°C ~ 50°C) (nonfreezing)

|

Ambient Humidity

|

-

85% or less (noncondensing)

|

Shaft Runout

|

-

0.002 in. (0.05 mm) T.I.R. at top of output shaft

|

Concentricity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Perpendicularity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Radial Play

|

-

0.001 in. (0.025 mm) max. of 1.12 lb. (5 N)

|

Axial Play

|

-

0.003 in. (0.075 mm) max. of 2.2 lb. (10 N)

|

Radial Load

|

-

0 in. from Shaft End = 3.3 lb0.2 in. from Shaft End = 3.8 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 5.1 lb0 mm from Shaft End = 15 N5 mm from Shaft End = 17 N10 mm from Shaft End = 20 N15 mm from Shaft End = 23 N

|

Axial Load

|

-

2.2 lb10 N

|

![]()