CAD / Búsqueda Manual

Para encontrar CAD y Manuales de Operador de nuestros products, por favor realice la búsqueda usando el número de item

![]()

Para Inglés o Español:

Para japonés:

Clientes de Mexíco:

Servicio Al Cliente - +001-847-871-5931

Soporte técnico - 01-800-681-5309

Clientes Internacionales:

+1-847-871-5931 o

+1-310-715-3304

Para soporte en productos del catálogo japonés:

1-800-746-6872 o

+1-310-715-3304

El contenido a continuación está en inglés

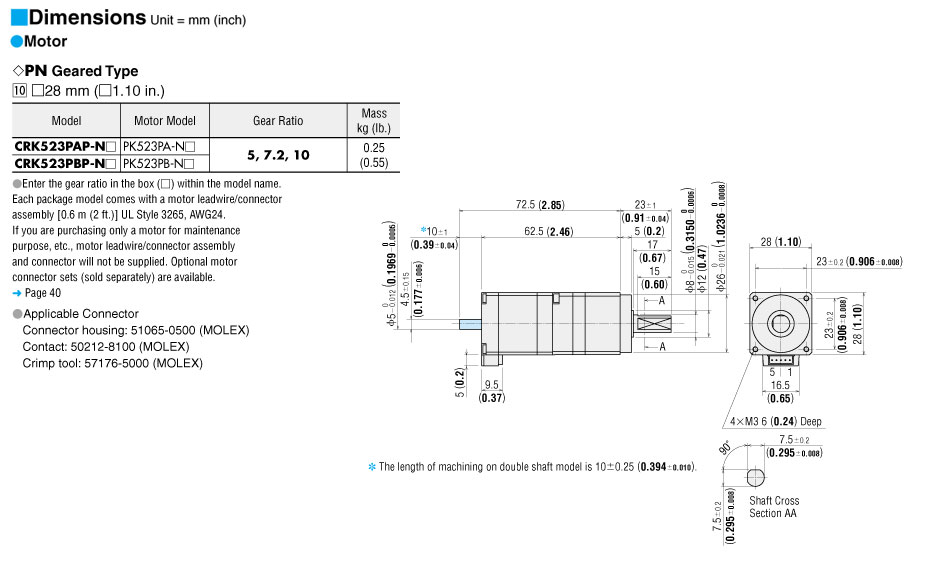

Compatible Motors (sold separately)

|

|

|

|

|

|