CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.

Oriental Motor offers a wide range of motion control products to meet a wide range of applications, select the appropriate application type below.

We're Here to Help

Business Hours - Monday to Friday, 8:30am EST to 5:00pm PST

U.S.A. Customers:

Customer Service - 1-800-418-7903

Tech Support – 1-800-GO-VEXTA (468-3982)

International Customers:

+1-847-871-5931 or

+1-310-715-3303

For Japanese:

1-800-746-6872 or

+1-310-715-3303

The AZ Series offers closed loop control, substantially reduces heat generation from the motor and by incorporating the newly developed Mechanical Absolute Encoder, absolute-type positioning is available, without battery back-up or external sensors to buy. Requires AZ Series Driver.

- 1.65 in. (42 mm) Frame Size

- Battery-Free, Mechanical Absolute Encoder

- AC Input

- Geared Type Available

- Electromagnetic Brake Type Available

| Items |

/Asset/azm46ac-img.jpg /Asset/azm46ac-img.jpg AZM46AC 1.65 in. (42mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $307.00

|

/Asset/azm46mc-img.jpg /Asset/azm46mc-img.jpg AZM46MC 1.65 in. (42mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $466.00

|

/Asset/azm46ac-ts_-img.jpg /Asset/azm46ac-ts_-img.jpg AZM46AC-TS3.6 1.65 in. (42mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $441.00

|

/Asset/azm46ac-ts_-img.jpg /Asset/azm46ac-ts_-img.jpg AZM46AC-TS7.2 1.65 in. (42mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $441.00

|

/Asset/azm46ac-ts_-img.jpg /Asset/azm46ac-ts_-img.jpg AZM46AC-TS10 1.65 in. (42mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $457.00

|

|||||

| Frame Size | - 1.65 in42 mm | |||||||||

| Motor Length | - 2.76 in.70 mm | - 3.98 in.101 mm | - 3.98 in.101 mm | - 3.98 in.101 mm | - 3.98 in.101 mm | |||||

| Driver Voltage Input Power | - AC | |||||||||

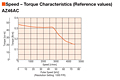

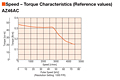

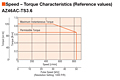

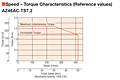

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

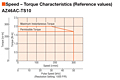

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

|

Holding Torque |

- 42 oz-in0.30 N·m | - 42 oz-in0.30 N·m | - 92 oz-in0.65 N·m | - 170 oz-in1.20 N·m | - 240 oz-in1.70 N·m | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - | - 3.6 :1 | - 7.2 :1 | - 10 :1 | |||||

| Backlash | - | - | - 45 arc min (0.75°) | - 25 arc min (0.42°) | - 25 arc min (0.42°) | |||||

| Lost Motion | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | - Equipped | - Not Equipped | - Not Equipped | - Not Equipped | |||||

| Permissible Speed Range (r/min) | - | - | - 0 ~ 833 | - 0 ~ 416 | - 0 ~ 300 | |||||

| Rotor Inertia | - 0.30 oz-in²55×10-7 kg·m² | - 0.39 oz-in²71×10-7 kg·m² | - 0.30 oz-in²55×10-7 kg·m² | - 0.30 oz-in²55×10-7 kg·m² | - 0.30 oz-in²55×10-7 kg·m² | |||||

|

RoHS Compliant |

- These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

|

Safety Standards |

- UL CE | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb0 mm from Shaft End = 35 N5 mm from Shaft End = 44 N10 mm from Shaft End = 58 N15 mm from Shaft End = 85 N | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb0 mm from Shaft End = 35 N5 mm from Shaft End = 44 N10 mm from Shaft End = 58 N15 mm from Shaft End = 85 N | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 6.7 lb0.39 in. from Shaft End = 9 lb0.59 in. from Shaft End = 11.2 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 30 N10 mm from Shaft End = 40 N15 mm from Shaft End = 50 N | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 6.7 lb0.39 in. from Shaft End = 9 lb0.59 in. from Shaft End = 11.2 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 30 N10 mm from Shaft End = 40 N15 mm from Shaft End = 50 N | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 6.7 lb0.39 in. from Shaft End = 9 lb0.59 in. from Shaft End = 11.2 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 30 N10 mm from Shaft End = 40 N15 mm from Shaft End = 50 N | |||||

| Permissible Thrust Load | - 0.96 lb4.30 N | - 1.35 lb6 N | - 3.30 lb15 N | - 3.30 lb15 N | - 3.30 lb15 N | |||||

| Permissible Thrust Load | - | |||||||||

|

|

||||||||||