CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.

Oriental Motor offers a wide range of motion control products to meet a wide range of applications, select the appropriate application type below.

We're Here to Help

Business Hours - Monday to Friday, 8:30am EST to 5:00pm PST

U.S.A. Customers:

Customer Service - 1-800-418-7903

Tech Support – 1-800-GO-VEXTA (468-3982)

International Customers:

+1-847-871-5931 or

+1-310-715-3303

For Japanese:

1-800-746-6872 or

+1-310-715-3303

1-800-GO-VEXTA (468-3982)

AC Input AR Series 2.36 in. (60 mm) NEMA 24 Closed Loop Stepper Motors

AR Series Short Range Servo Motors

The AR Series adopts our AlphaStep technology closed loop control so the motor does not lose synchronism even when subjected to abrupt load fluctuation or acceleration. Requires AR Series Driver.

- 2.36 in. (60 mm) Frame Size

- Closed Loop

- AC Input

- Single or Double Shaft

- Geared Type Available

- Electromagnetic Brake Type Available

Unit of Measure

| Items |

/Asset/pcj_arm66acd.jpg /Asset/pcj_arm66acd.jpg ARM66AC 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $192.00

|

/Asset/pcj_arm66a-td.jpg /Asset/pcj_arm66a-td.jpg ARM66AC-T3.6 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $311.00

|

/Asset/pcj_arm66a-td.jpg /Asset/pcj_arm66a-td.jpg ARM66AC-T7.2 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $311.00

|

/Asset/pcj_arm66a-td.jpg /Asset/pcj_arm66a-td.jpg ARM66AC-T10 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $323.00

|

/Asset/pcj_arm66a-td.jpg /Asset/pcj_arm66a-td.jpg ARM66AC-T20 2.36 in. (60 mm) Closed Loop Stepper Motor Web Price $323.00

|

|||||

| Frame Size | - 2.36 in60 mm | |||||||||

| Motor Length | - 2.54 in.64.5 mm | - 4.33 in.110 mm | - 4.33 in.110 mm | - 4.33 in.110 mm | - 4.33 in.110 mm | |||||

| Driver Voltage Input Power | - AC | |||||||||

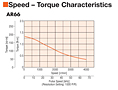

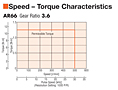

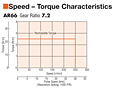

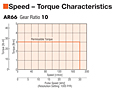

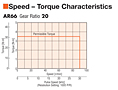

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

|

Holding Torque |

- 170 oz-in1.2 N·m | - 176 oz-in1.25 N·m | - 352 oz-in2.5 N·m | - 416 oz-in3 N·m | - 480 oz-in3.5 N·m | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - 3.6 :1 | - 7.2 :1 | - 10 :1 | - 20 :1 | |||||

| Backlash | - | - 35 arc min (0.584°) | - 15 arc min (0.25°) | - 15 arc min (0.25°) | - 10 arc min (0.167°) | |||||

| Lost Motion | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Permissible Speed Range (r/min) | - | - 0 ~ 500 | - 0 ~ 250 | - 0 ~ 180 | - 0 ~ 90 | |||||

| Rotor Inertia | - 2.1 oz-in²380×10-7 kg·m² | |||||||||

|

RoHS Compliant |

- These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

|

Safety Standards |

- UL CSA EN CE | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb0 mm from Shaft End = 90 N5 mm from Shaft End = 100 N10 mm from Shaft End = 130 N15 mm from Shaft End = 180 N20 mm from Shaft End = 270 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | |||||

| Permissible Thrust Load | - 1.98 lb8.80 N | - 9 lb40 N | - 9 lb40 N | - 9 lb40 N | - 9 lb40 N | |||||

| Permissible Thrust Load | - | |||||||||

|

|

||||||||||