ORIENTAL MOTOR U.S.A. Corp.

1001 Knox Street

Torrance, CA 90502

1-800-GO-VEXTA (468-3982)

ORIENTAL MOTOR U.S.A. Corp.

1001 Knox Street

Torrance, CA 90502

1-800-GO-VEXTA (468-3982)

| Items |

PKE543MC 1.65 in. (42 mm) 5-Phase Stepper Motor with Brake (AC Input) Web Price $217.00

|

PKE544MC 1.65 in. (42 mm) 5-Phase Stepper Motor with Brake (AC Input) Web Price $218.00

|

PKE545MC 1.65 in. (42 mm) 5-Phase Stepper Motor with Brake (AC Input) Web Price $226.00

|

PKE543MC-HS50 1.65 in. (42 mm) 5-Phase Geared Stepper Motor with Brake (AC Input) Web Price $876.00

|

PKE543MC-HS100 1.65 in. (42 mm) 5-Phase Geared Stepper Motor with Brake (AC Input) Web Price $876.00

|

|||||

| Frame Size | - 1.65 in | |||||||||

| Motor Length | - 1.34 in. | - 1.57 in. | - 1.81 in. | - 1.34 in. | - 1.34 in. | |||||

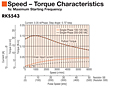

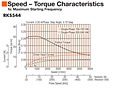

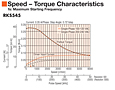

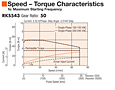

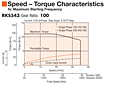

| Speed-Torque Characteristics |

-

|

-

|

-

|

-

|

-

|

|||||

| Holding Torque | - 19.8 oz-in | - 29 oz-in | - 38 oz-in | - 480 oz-in | - 704 oz-in | |||||

| Type | - Standard | - Standard | - Standard | - Geared | - Geared | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Harmonic Gear | - Harmonic Gear | |||||

| Gear Ratio (X:1) | - | - | - | - 50 :1 | - 100 :1 | |||||

| Backlash | - | |||||||||

| Encoder Resolution | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Equipped | |||||||||

| Current | - 0.35 A | |||||||||

| Basic Step Angle | - 0.72° | - 0.72° | - 0.72° | - 0.0144° | - 0.0072° | |||||

| Permissible Speed Range (r/min) | - | - | - | - 0 ~ 70 | - 0 ~ 35 | |||||

| Rotor Inertia | - 0.25 oz-in² | - 0.34 oz-in² | - 0.43 oz-in² | - 0.34 oz-in² | - 0.34 oz-in² | |||||

| Lost Motion | - | - | - | - 1.5 arc min maximum | - 1.5 arc min maximum | |||||

| Permissible Overhung Load | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb | - 0 in. from Shaft End = 40 lb0.2 in. from Shaft End = 49 lb0.39 in. from Shaft End = 60 lb0.59 in. from Shaft End = 81 lb0.79 in. from Shaft End = 114 lb | - 0 in. from Shaft End = 40 lb0.2 in. from Shaft End = 49 lb0.39 in. from Shaft End = 60 lb0.59 in. from Shaft End = 81 lb0.79 in. from Shaft End = 114 lb | |||||

| Permissible Thrust Load | - 0.56 lb | - 0.69 lb | - 0.83 lb | - 49 lb | - 49 lb | |||||

| Encoder Output | - | |||||||||

| Safety Standards | - UL CE | |||||||||

|

|

||||||||||