CAD / Búsqueda Manual

Para encontrar CAD y Manuales de Operador de nuestros products, por favor realice la búsqueda usando el número de item

![]()

Para Inglés o Español:

Para japonés:

Clientes de Mexíco:

Servicio Al Cliente - +001-847-871-5931

Soporte técnico - 01-800-681-5309

Clientes Internacionales:

+1-847-871-5931 o

+1-310-715-3304

Para soporte en productos del catálogo japonés:

1-800-746-6872 o

+1-310-715-3304

El contenido a continuación está en inglés

AC Input AZ Series 2.36 in. (60 mm) NEMA 24 Mechanical Absolute Encoder Stepper Motors

AZ Series Mechanical Absolute Encoder Short Range Servo Motors

The AZ Series offers closed loop control, substantially reduces heat generation from the motor and by incorporating the newly developed Mechanical Absolute Encoder, absolute-type positioning is available, without battery back-up or external sensors to buy. Requires AZ Series Driver.

- 2.36 in. (60 mm) Frame Size

- Battery-Free, Mechanical Absolute Encoder

- AC Input

- Geared Type Available

- Electromagnetic Brake Type Available

Unit of Measure

| Items |

/Asset/azm66ac-img.jpg /Asset/azm66ac-img.jpg AZM66AC 2.36 in. (60 mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $362.00

|

/Asset/azm66mc-img.jpg /Asset/azm66mc-img.jpg AZM66MC 2.36 in. (60 mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $565.00

|

/Asset/azm69ac-img.jpg /Asset/azm69ac-img.jpg AZM69AC 2.36 in. (60 mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $367.00

|

/Asset/azm66mc-img.jpg /Asset/azm66mc-img.jpg AZM69MC 2.36 in. (60 mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $571.00

|

/Asset/azm66ac-ts_-img.jpg /Asset/azm66ac-ts_-img.jpg AZM66AC-TS3.6 2.36 in. (60 mm) Mechanical Absolute Encoder, Closed Loop Stepper Motor Web Price $519.00

|

|||||

| Frame Size | - 2.36 in60 mm | |||||||||

| Motor Length | - 2.83 in.72 mm | - 4.65 in.118 mm | - 3.84 in.97.50 mm | - 5.65 in.143.50 mm | - 4.53 in.115 mm | |||||

| Driver Voltage Input Power | - AC | |||||||||

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

|

Holding Torque |

- 170 oz-in1.20 N·m | - 170 oz-in1.20 N·m | - 280 oz-in2 N·m | - 280 oz-in2 N·m | - 255 oz-in1.80 N·m | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - | - | - | - 3.6 :1 | |||||

| Backlash | - | - | - | - | - 35 arc min (0.59°) | |||||

| Lost Motion | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | - Equipped | - Not Equipped | - Equipped | - Not Equipped | |||||

| Permissible Speed Range (r/min) | - | - | - | - | - 0 ~ 833 | |||||

| Rotor Inertia | - 2 oz-in²370×10-7 kg·m² | - 2.90 oz-in²530×10-7 kg·m² | - 4 oz-in²740×10-7 kg·m² | - 4.90 oz-in²900×10-7 kg·m² | - 2 oz-in²370×10-7 kg·m² | |||||

|

RoHS Compliant |

- These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

|

Safety Standards |

- UL CE | |||||||||

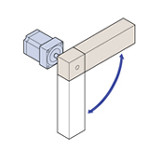

| Permissible Overhung Load | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb0 mm from Shaft End = 90 N5 mm from Shaft End = 100 N10 mm from Shaft End = 130 N15 mm from Shaft End = 180 N20 mm from Shaft End = 270 N | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb0 mm from Shaft End = 90 N5 mm from Shaft End = 100 N10 mm from Shaft End = 130 N15 mm from Shaft End = 180 N20 mm from Shaft End = 270 N | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb0 mm from Shaft End = 90 N5 mm from Shaft End = 100 N10 mm from Shaft End = 130 N15 mm from Shaft End = 180 N20 mm from Shaft End = 270 N | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb0 mm from Shaft End = 90 N5 mm from Shaft End = 100 N10 mm from Shaft End = 130 N15 mm from Shaft End = 180 N20 mm from Shaft End = 270 N | - 0 in. from Shaft End = 27 lb0.2 in. from Shaft End = 30 lb0.39 in. from Shaft End = 33 lb0.59 in. from Shaft End = 37 lb0.79 in. from Shaft End = 40 lb0 mm from Shaft End = 120 N5 mm from Shaft End = 135 N10 mm from Shaft End = 150 N15 mm from Shaft End = 165 N20 mm from Shaft End = 180 N | |||||

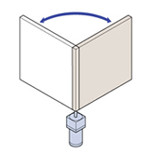

| Permissible Thrust Load | - 2 lb8.90 N | - 2.80 lb12.70 N | - 3.10 lb14 N | - 3.90 lb17.60 N | - 9 lb40 N | |||||

| Permissible Thrust Load | - | |||||||||

|

|

||||||||||